Some people find sometimes metal sheet can’ be cut through by laser cutting machine. It affects the processing capacity and production efficiency. The waste of materials will also have a certain impact on the laser cutting machine. Does it happen to you? Do you know the reason and how to solve it?

Why does this happen?

1. Laser power drop

After the fiber laser source is used for a long time, the power will gradually decrease with the use time, which will eventually lead to the decline of the cutting capacity, and the cutting failure will also occur.

2. The thickness of the metal sheet exceeds the cutting thickness of the equipment limit

Fiber laser cutting machines with different powers will have a limit cutting thickness. If the limit thickness is exceeded, the cutting effect of the equipment will be unsatisfactory, including the situation that plates can’t be cut through.

3. Optical element contamination

Optical elements include focusing lens, collimating lens, etc. because of long-term poor working environment, it is easy to leave residues on the surface of these lenses, which reduces the laser power of cutting head and leads to incompletely cutting.

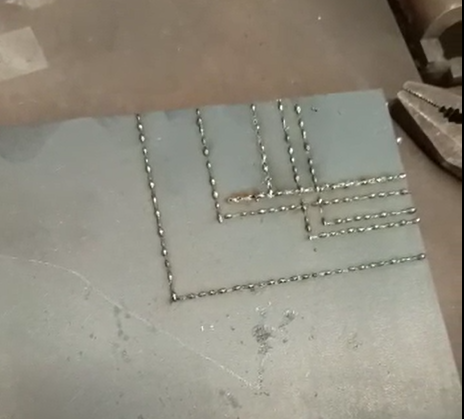

4. Equipment spot debugging is not up to standard

The spot of the fiber laser cutting head is the most important factor affecting the cutting quality. When the spot debugging fails to meet the standard, plates also can’t be cut through

5. The cutting speed is too fast

If the cutting speed is too fast, the situation of missing cutting will inevitably occur, which will lead to that situation

6. Insufficient auxiliary gas pressure

The auxiliary gas helps blow off the slag during cutting. When the air pressure is not reached, the slag is difficult to remove, which will lead to incompletely cutting.

What Can We Do?

1. Check whether the power of fiber laser source has dropped. If so, we should replace the laser tube in time, and use a smoother and larger voltage regulator to increase the laser current output and the output power.

2. We should appropriately reduce the cutting speed when cutting, and clean the contaminated lens in time and replace the focusing lens.

3. If the optical path is not correct, you can re-adjust the optical path and adjust the focal length until the laser makes a very round spot on the paper.

4. When cutting copper and aluminum, it is best to polish its surface in advance or apply light-absorbing material to deal with the problem of high reflectivity.

5. Regularly clean the foreign objects in the nozzle, increase the pressure of the auxiliary gas, and replace the distilled water of the cooling system in time.