From 2000 to 2018, there were 30000 sets of high-end CO2 laser cutting machines in the world; There are 15000 sets of Trumpf and Bystronic, accounting for 50% of the total market

Trumpf equipments have advanced technology, superior performance and long service life; However, the operation and maintenance cost of CO2 laser is higher.

Current Market Situation

According to survey data from one of market research agencies, the global market of fiber laser cutting machine will grow in a compound annual growth rate of about 7-8% in the next few years. It is expected that the market amount will reach $ 2.35 billion by 2024. From the current market possession of fiber laser cutting machines, it will still occupy a dominant position in the recent 5-10 years.

Since 2016, the laser cutting machine has occupied the market for thin plate metal processing market. At that time, it could greatly improve the efficiency and accuracy of thin plate processing, and once became a standard product for thin plate processing. In the past two years, in the field of metal cutting, fiber laser continues to develop towards higher power, and gradually replaced traditional cutting solutions in terms of cutting thickness and speed, and environmental protection and safety.

Current Situation Of CO2 Laser Cutting Machine Manufacturers

1. Equipment: The original machine is a high-end brand and costs a lot of money, it has excellent machine tool structure and excellent dynamic performance of CNC control system. It is a pity to eliminate products due to laser problems

2. Gas Cost: CO2 laser consumes laser gases to increase operating costs, The electro-optical conversion rate of CO2 laser is only 10%. Compared with fiber laser, the same power consumes higher energy, which reduce the competition rate of manufacturers

3. Higher Maintenance Cost: traditional CO2 laser uses mirror reflection with complicated structure, which cause complicated maintenance, and high maintenance costs;

4. Economic Situation: The cost of purchasing a new machine is too high, investment needs to be cautious in the current economic market.

Difficulties To Retrofit/Upgrade

There are many companies trying to retrofit CO2 to fiber laser but failed.

1. Underlying data transmission of Trumpf is complex.

2. The model and interface of the original laser are special and cannot be upgraded. Trumpf use self-made laser source and cutting head, Siemens CNC

3. Few people are proficient in CO2 lasers and fiber lasers at the same time.

Trumpf Retrofit/Upgrade Solution

Newlaz team consists of experienced experts who are familiar with Trumpf system, CO2 and fiber laser. They were devoted to researching and developing an efficient retrofit/upgrade solution.

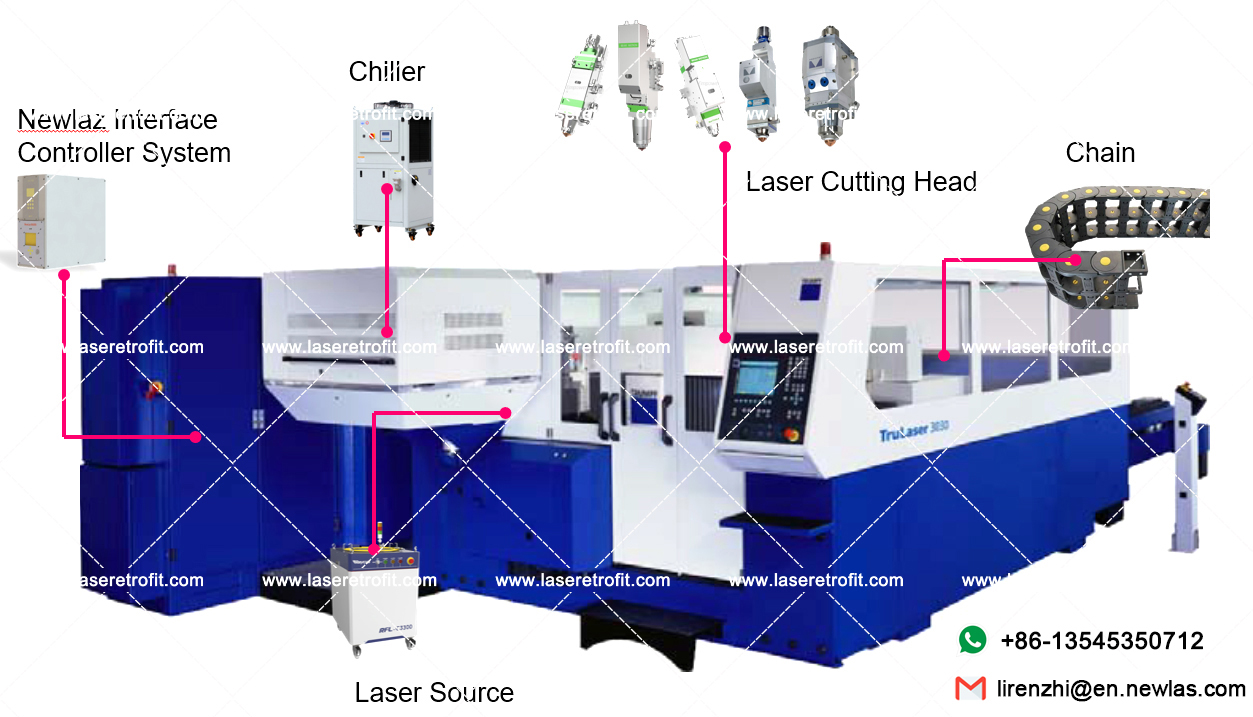

new fiber laser source+ laser cutting head+ new chiller+ new chain+ newlaz controller= A New Set Of Fiber Laser Cutting Machine

Advantages

1. Easy to install: only need to exchange five parts, then your machine will be freshened up

2. Efficiency: time is money, it only takes about 3 days to install, then your machine can be worked as a fiber laser cutting machine, your production schedule won’t be delayed too much.

3. Warranty:

- 2 years warranty for fiber laser source

- 24h technical support

Your Economic Benefits

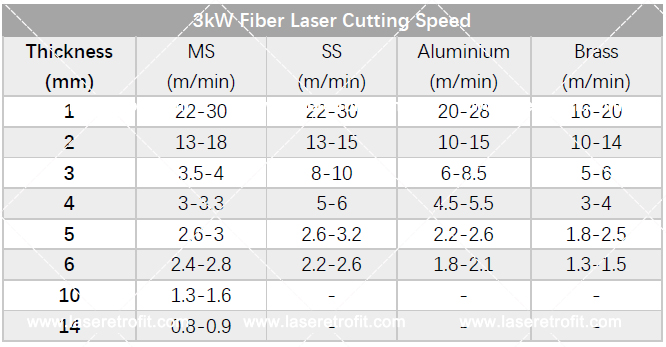

No matter what you did, economic benefits is the final purpose. Newlaz’s Trumpf retrofit solution can bring you with faster cutting speed, higher production capability, lower maintenance cost, etc.

1. Faster cutting speed:

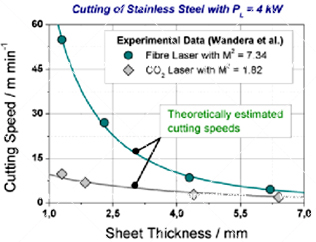

When thicknesss is less than 7 mm, cutting speed of fiber laser is faster than CO2 lasers.

2. Higher production capability

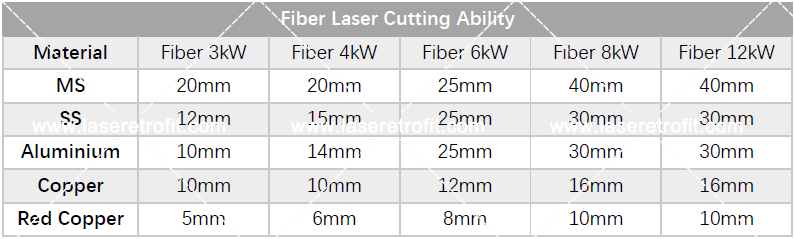

After upgrading, you can also cut high reflective metal sheet, such as brass, copper, etc

3. Lower maintenance cost

Fiber laser don’t need gas to generate laser and can use air to cut, gas cost will be reduced greatly.

4. Original CNC system

Our retrofit solution is to keep existing operating methods you are familiar with, you don’t need to spend extra time to learn and adapt to a new and complex operating system.

Retrofit Cases

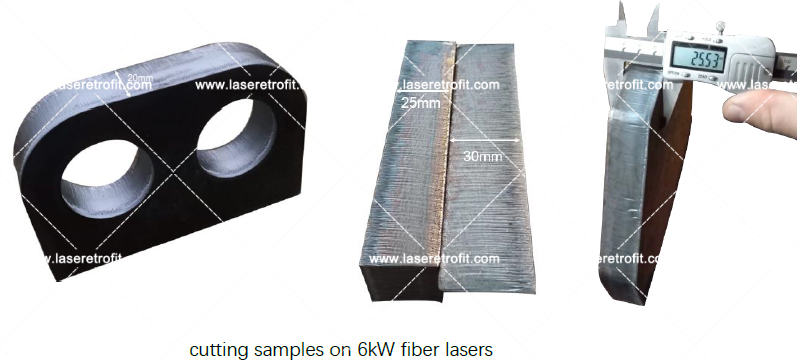

Cutting Samples