The process of laser cutting is the process of absorbing light energy and turning it into heat energy and making the material melt and vaporize.

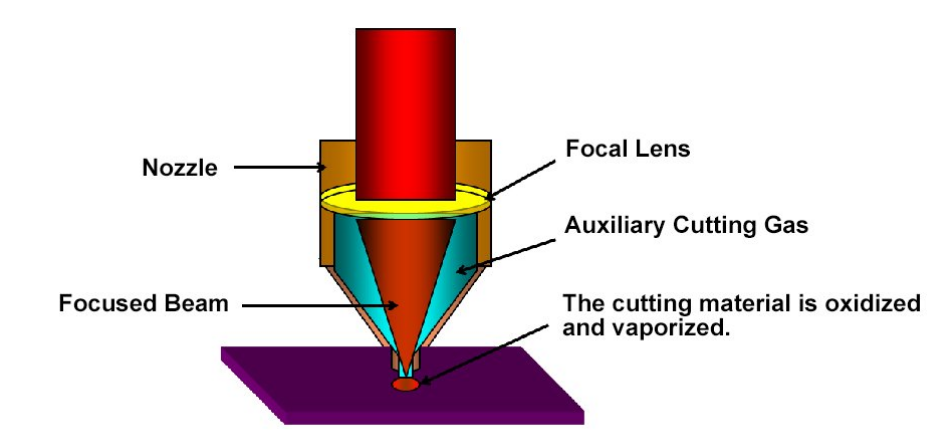

• The laser beam with high energy density output by the laser generator.

• The beam is focused through the focusing lens and the energy is highly concentrated.

• The focused beam passes through the center of the nozzle, and the nozzle ejects out auxiliary cutting gas which axis is the same as the light path.

• Under the joint action of the laser beam and cutting gas, the cutting material is rapidly heated, oxidized and evaporated to achieve the cutting purpose.

The basic principle of laser cutting is the interaction between laser and matter.

It contains both the complex microscopic quantum processes and the macroscopic phenomena of the laser acting on various media materials.

These macroscopic phenomena include the absorption, reflection, refraction, energy conversion and transmission of the material to the laser, the material status and ambient gas composition, the tissue effect of a light beam on a material surface etc.

Therefore, the factors that affect the quality of laser cutting are very complicated.

In addition to the processing material itself, it is mainly light beam characteristics, laser power, cutting speed, nozzle type (aperture) and nozzle height, focus position, auxiliary gas type and pressure, etc.

The effect of the beam on cutting quality

The width of laser cutting is closely associated with the beam mode and the focal spot diameter.

Since the power density and energy density of laser irradiation is related to the diameter of the laser spot, the diameter of the spot should be as small as possible in laser cutting in order to obtain greater power density and energy density.

The size of the spot diameter depends on the diameter of the laser beam output by the oscillator and its divergence angle. It is also related to the focal length of the focusing lens.

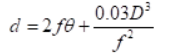

For the wide application of ZnSe flat convex focusing lens in general laser cutting, the relationship between the spot diameter d and the focal length f, the divergence angle 6 and the diameter D of the incident laser beam can be calculated according to the following formula:

It can be seen from the above equation that if the laser beam itself has a smaller divergence angle, the diameter of the spot will also be smaller, thus achieving a good cutting effect.

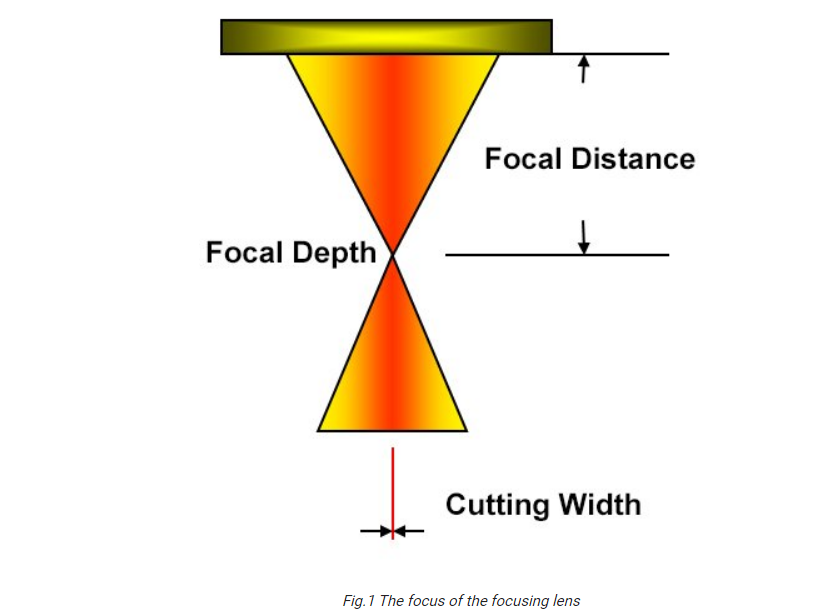

Reducing lens focal length f is beneficial to reducing spot diameter. However, if f is reduced, the focal depth will be shortened, it is not conducive to obtaining the equal width of the incision on both the upper and lower section for the cutting of thicker plates, which will affect the quality of the slit.

At the same time, the distance between the lens and the workpiece is reduced if reducing f. When cutting, the slag will splash on the surface of the lens, which will affect the normal operation of the cutting and the service life of the lens.

The focal length of the lens is small, the power density of the beam is high, but the focal depth is limited.

It is suitable for high – speed cutting of thin plate, just ensure that the spacing of lens and workpiece is constant.

The long focal lens has low power density, but it has a large focal depth and can be used to cut thick sections of material.

The shorter the focal length, the smaller the focal spot; the longer the focal length, the larger the focal spot. This is also applied to focal depth changes.

When the lens focal length increases to double the focal spot size, i.e. from Y to 2Y the focal depth can be increased to four times, i.e, from X to 4X.

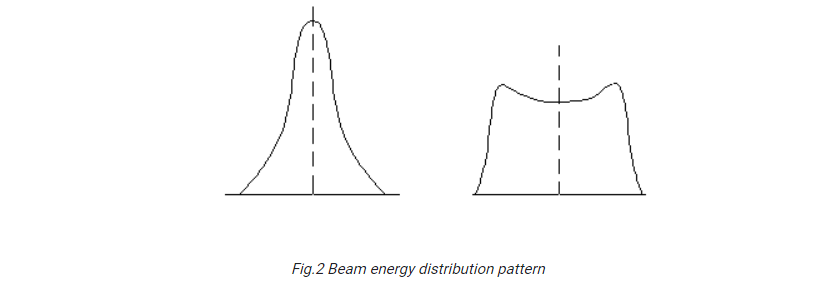

The beam pattern is related to its focusing ability, which is somewhat similar to the sharp edge of the mechanical tool.

The lowest order mode is TEMOO, and the energy in the spot presented gaussian-like distribution.

It can almost focus the beam on the theoretical smallest size, such as a few micron diameters, and form a pointed high energy density.

The laser mode is as shown in the fig.

The energy distribution of the high-order or multi-mode beam is more expansive. The focused light spot is larger and the energy density is lower. Using it to cut material is like cutting with a blunt knife.

The lower the mode of the beam, the smaller the spot size, the greater the power density and the energy density, the better the cutting performance.

In the cutting of low carbon steel, the cutting speed of the base mode TEMOO is 10% higher than that of the TEM01 mode, and the roughness Rz produced by it is lower by 10pm. In the best cutting parameters, the roughness Rz of the cutting surface is only 0.8pm.

Therefore, in the laser cutting of metal materials, the laser of TEMOO mode is generally used to obtain higher cutting speed and better cutting quality.

cr: machinemfg