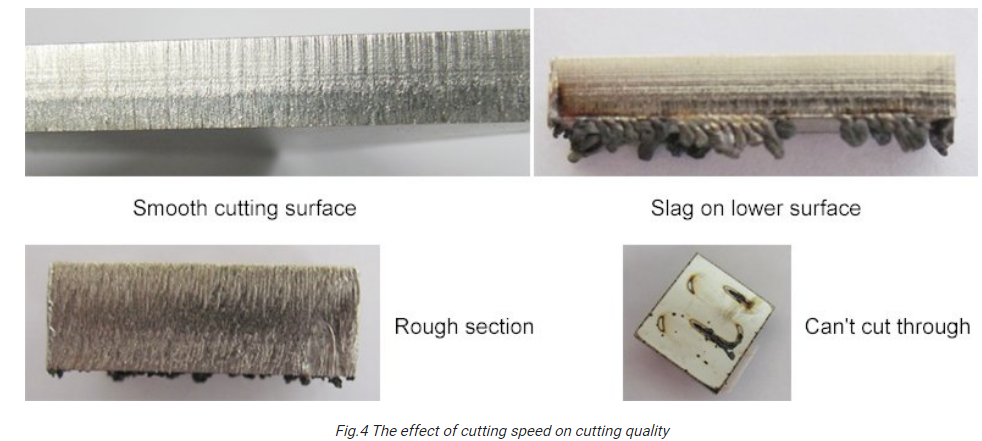

The cutting speed has a great influence on the cutting quality of the stainless steel plate. The best cutting speed makes the cutting surface smooth and the bottom is free of slag.

If the cutting speed is too fast it will cause the steel plate to be unable to cut through, causing the sparks to splash and the lower half to produce slag and even burn the lens. This is because the cutting speed is too high, the energy per unit area is reduced and the metal is not completely melted.

If the cutting speed is too slow, it is easy to cause the material to melt, the cutting seam becomes wider, the thermal influence area increases, and even the workpiece is burnt. This is because the cutting speed is too low, the energy accumulates at the cutting edge, causes the slit to widen, the molten metal cannot be discharged in time, and the lower surface of the steel plate is formed with slag.

It produces the cutting defect as shown in figure 4.

The cutting speed and the laser output power determine the input heat of the workpiece

Therefore, the relationship between input heat change and processing quality caused by the increase and decrease of cutting speed is the same as that of output power.

In general, when the processing conditions are adjusted, the output power and cutting speed will not be changed at the same time if the input heat is changed. Just to fix one side and change the other side to adjust the processing quality.

The influence of nozzle type (aperture) and nozzle height on cutting quality

The nozzle shape (aperture), nozzle height (the distance between the nozzle outlet and the surface of the workpiece) can affect the cutting effect.

cr: machinemfg