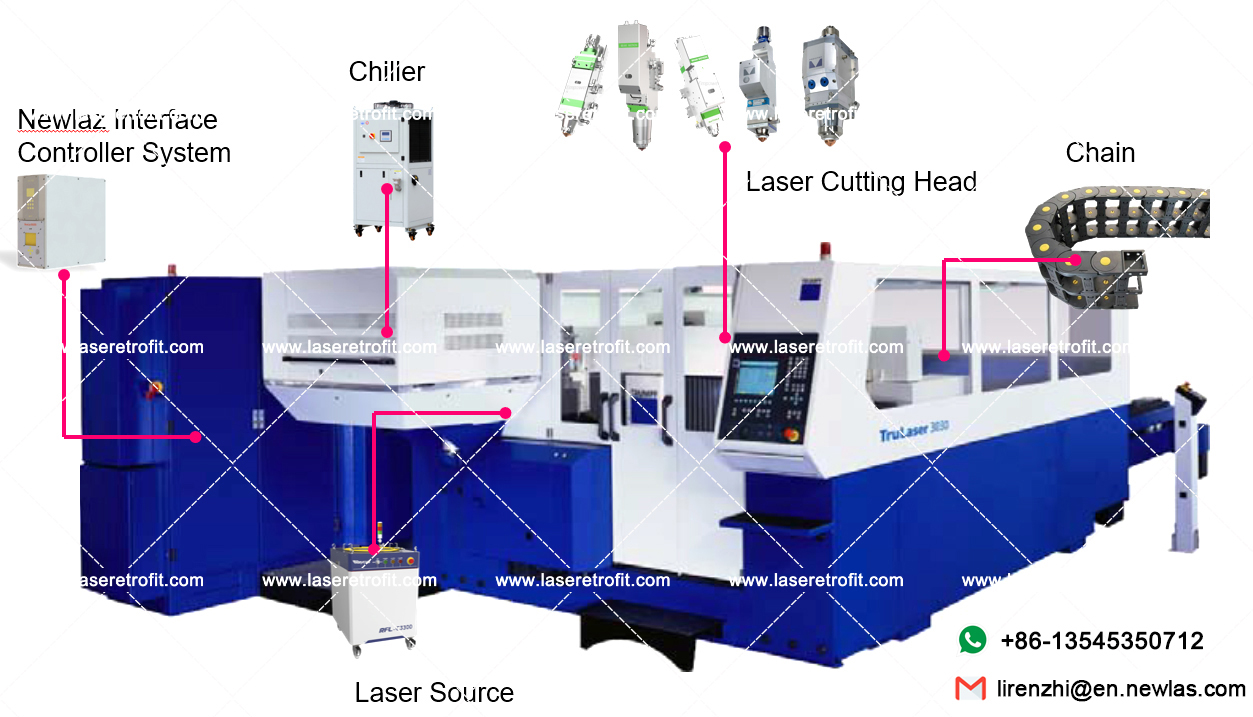

Newlaz retrofit TRUMPF CO2 laser cutting machine in the world. Increasingly complex business prompted our customers to upgrade their existing TRUMPF CO2 laser cutting machine with fiber laser source, like 3KW, 6KW, 12KW for their machine.

Retrofit Advantages

Fiber Laser

- Speed – Faster than CO2 lasers in thin materials as the laser can be absorbed quickly with a slight lead in speed when cutting with Nitrogen (fusion cutting).

- Cost per part – less than the CO2 laser depending on sheet thickness.

- Safety – Strict safety precautions must be taken (machine is completely enclosed) as the laser light (1µm) can pass through very narrow openings in the machine’s frame causing irreparable damage to the eye’s retina.

- Beam guidance – fiber optics.

CO2 Laser

- Quality – Quality is consistent throughout all thicknesses of material.

- Flexibility – high, suitable for all material thicknesses.

- Safety – CO2 laser light (10µm) is better absorbed by the machine frame, which lowers the risk of irreparable damage to the retina. Personnel should not look directly at the cutting process through the acrylic pane in the door as the bright plasma also presents a risk to sight over a period of time. (Similar to looking at the sun.)

- Beam guidance – mirror optics.

- Cutting with Oxygen (flame cutting) – there is no difference in quality or speed shown between the two types of lasers.

Retrofit Solution

Newlaz keep all TRUMPF advantages for the machine, including SIEMENS 840D system, Trutops sw, Switch Cabinet. We already tested TASC200, TASC3, TASC4 solution. we can work together with Trumpf machine for mass production.

Retrofit Project Gllery