| Trumpf PN | Size |

| 1792250 | 24*5mm |

| 0766719 | 30*5mm |

| 1614767, 1614797 | 34*5mm |

| 1887343 | 38*7mm |

| 0759720, 0798142, 1584792, 1615516 | 55*1.5mm |

| T1064 Vis Q /1254813 | 134*3mm |

There are two kinds of lenses inside the laser cutting head: collimating lens and focusing lens, which are sensitive to any type of contamination, especially the material splatter when cutting the metal.

The protective lens is between collimating/focusing lens and the metal sheet. it is one of the optical elements with high consumption in fiber laser cutting head. As it can protect focusing lens and collimating from back spatter and debris to ensure the optic system working stability during cutting.

What’s more, it’s inexpensive relatively comparing the cost of collimating lens and focusing lens.

Below are some advantages of our protective lens:

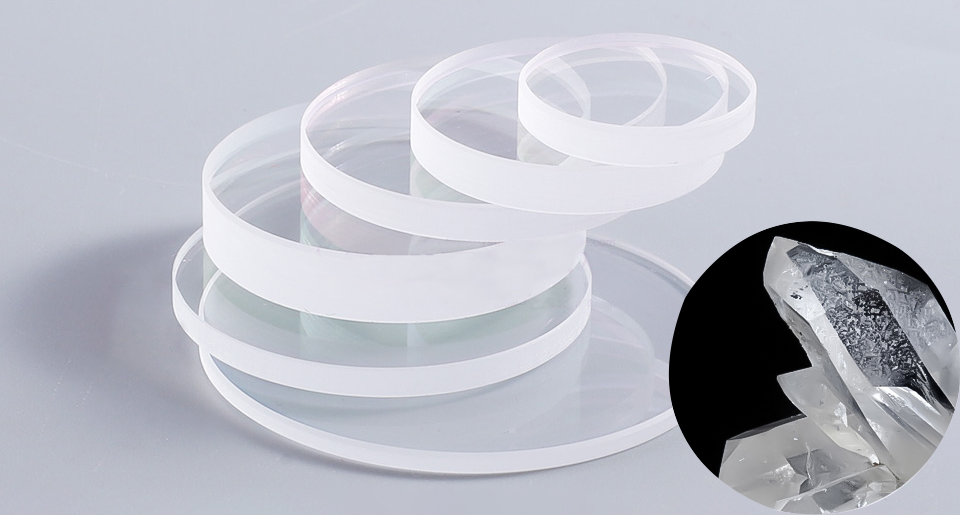

1. High quality of raw material: quartz material is with uniform texture, high mechanical strength and high resistance of pressure. Then lens is not easy to crack and collapse.

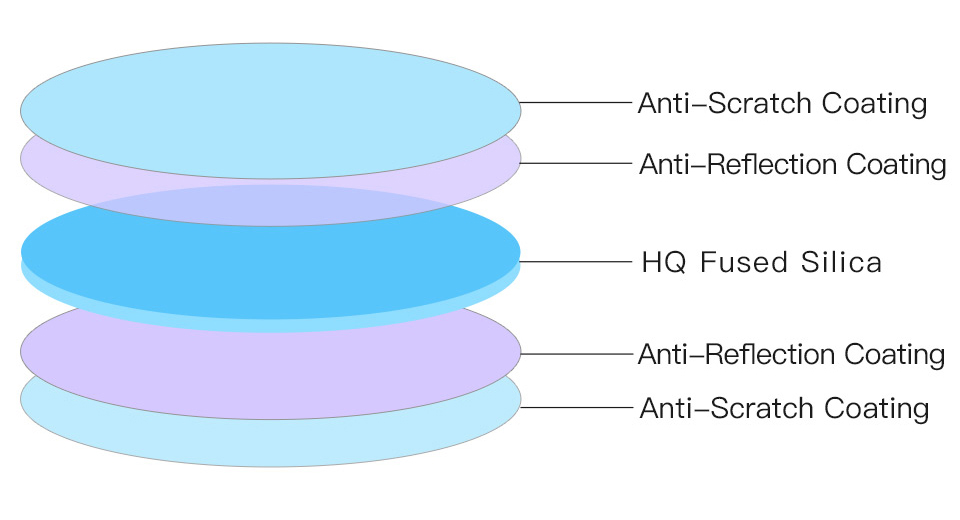

2. Double coating: anti-reflection film with high damage threshold is coated on both sides to reduce the loss caused by reflection and protect it from splash and other hazards.

3. 45°0.5mm protection angle: humanized 45° protective full-angle designed with convenient application. It’s safety, hand hurts will be avoided. Smooth edge will improve cutting speed.

4. High temperature resistant and laser resistant: excellent substrate is selected, which has excellent optical performance and good thermal stability. The lens is resistant to high temperature resistant and has strong laser performance after slicing, polishing and other high-precision process.

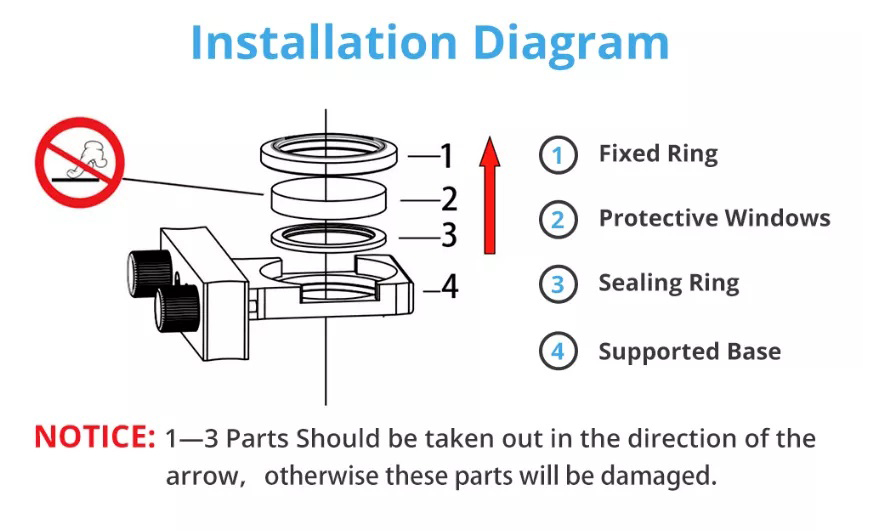

The protective lens is a consumable item in the optical path system of the laser cutting head. In order to reduce the use cost as much as possible. You need to pay more attention to avoid polluting or damaging the lenses as much as possible during the placement, inspection and installation of protective lenses.