Fiber laser cutting has the advantages of small spot, high energy density, fast cutting speed, etc., and can obtain better cutting quality. Among them, one of the key factors affecting the cutting efficiency is the nozzle.

Nozzle is one of the important parts in laser cutting head, which is located at the bottom of the cutting head. Laser beam and auxiliary gas are emitted through the nozzle. Its main function is to collect auxiliary gas and form high pressure, then release it to the surface of the metal sheet and the cutting seam, blow away the molten and vaporized base material generated during the cutting process, and leave a clean cutting seam. It can prevent slag, smoke and other pollutants from rebounding upward, and protect the inner lens at the same time.

Usually nozzles are divided into single-layer nozzles and double-layer nozzles. Single-layer nozzles are usually used for cutting stainless steel, aluminum, copper, etc., and nitrogen is generally used as auxiliary gas. Due to high gas flow rate, double-layer nozzles are often used for high-speed cutting and oxygen cutting of carbon steel, but the cutting surface will become black due to oxidation.

The nozzle determines the gas flow rate into the base metal and kerf, which affects melt removal. The greater and faster the airflow into the cut, the greater the ability of the jet to remove melt. In theory, the thicker the plate, the larger the nozzle should be used. However, the larger the nozzle aperture, the greater the possibility of sparks splashing upward during cutting, and the shorter the service life of the lens.

| Item | Newlaz’s Code | Model | Description | Nozzle Diameter |

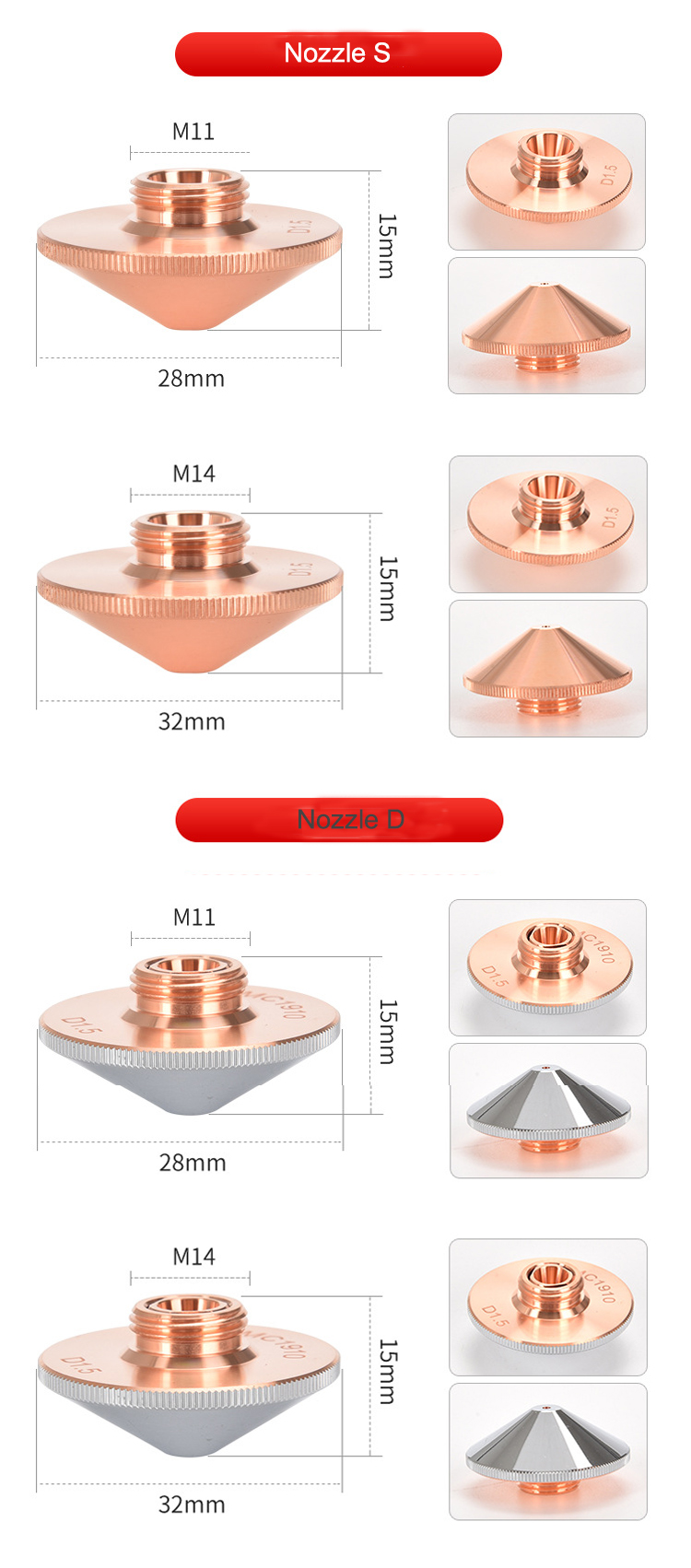

| 1 | PCT106008-PCT106050 | Nozzle S | D28, M11, H15 | 0.8-5.0mm |

| 2 | PCT106008-PCT106050 | Nozzle S | D32, M14, H15 | 0.8-5.0mm |

| 3 | PCT105008-PCT105050 | Nozzle D | D28, M11, H15 | 0.8-5.0mm |

| 4 | PCT105008-PCT105050 | Nozzle D | D32, M14, H15 | 0.8-5.0mm |

| 5 | RTL107008-RTL107050 | Nozzle X | D28, M11, H15 | 0.8-5.0mm |

| 6 | RTL107008-RTL107050 | Nozzle X | D28, M11, H15 | 0.8-5.0mm |

| 7 | RTL108020-RTL108050 | Nozzle C | D28, M11, H15 | 2.0-5.0mm |

| 8 | RTL108020-RTL108050 | Nozzle C | D32, M14, H15 | 2.0-5.0mm |

| 9 | RTL108008-RTL108050 | Nozzle E | D28, M11, H15 | 0.8-5.0mm |

| 10 | RTL108008-RTL108050 | Nozzle E | D32, M14, H15 | 0.8-5.0mm |

1. High quality material: good quality copper with high temperature resistance, radiate quickly, high sensibility.

2. Good cutting quality: produced by automatic machine, the inner wall is smooth so that the airflow can pass without obstacles, and the cutting speed is fast

3. Delicate craft: strict anti-oxidation process, bright and clean surface, longer service life