| Item | Lightcutter 2.0 | Lightcutter 2.0 | Procutter 2.0 | Procutter 2.0 |

| Max laser power | 3kW | 6kW | 8kW | 15 – 30 kW |

| Focus length of collimating lens | 75mm, 100mm | 100mm | 100mm | 100mm |

| Focal length of focusing lens | 100mm, 125m, 150mm, 200mm | 125m, 150mm, 200mm | 125,150,175,200mm | 150,200mm |

| N/A max | 0.16(FC75), 0.12(FC100) | 0.12(FC100) | 0.13 | 0.13 |

| Axial length | / | / | 313mm(FF125) | 363mm(FF150-QBH,D) |

| Vertical adjustment range | +3 мм / – 5 мм | +11 мм / -8 мм | +6 /-9 mm (FF125) +15 /-20 mm (FF200) | +10 /-16 mm (FF150) +15/-30 mm (FF200, 15/20 kW) +25/-30 mm (FF200, 30 kW) |

| Dimension (WxD) | 75*69mm | 130*69mm | 96*134mm | 96*134mm |

| Weight | 3.3kg | 4.0kg | 6.2kg | 6.3kg |

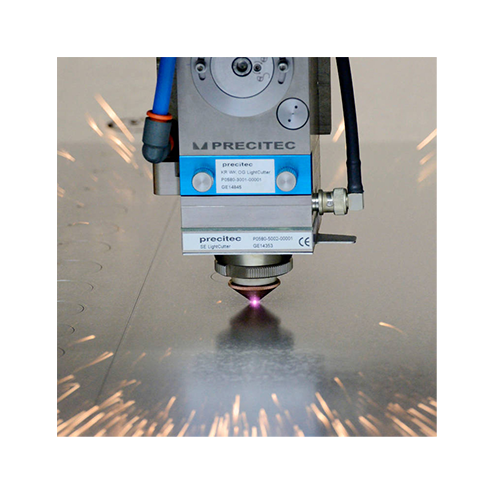

LightCutter 2.0

Efficient And Economical In The Medium Power Range

The LightCutter 2.0 is the ideal solution for all laser cutting applications in the medium power range up to 6 kW. Even if 2D has wide range of variants, you will always find the most efficient and economical configuration. It is characterized by high cutting qualities for all metals up to 25 mm sheet thickness, especially for laser cutting of mild steel, stainless steel, and aluminum.

The adjustment of the axial focus position is CNC-controlled. The cutting head is stable at accelerations of up to 3 g. The display of the set focus position on the front of the cutting head makes commissioning much easier. The LightCutter 2.0 Motorized covers a large focus position range of 23 mm in total.

1. Higher cutting speeds and higher quality cutting edges: optimized for continuous permanent operation, it scores points with high cutting speeds and smooth, rectangular edges with minimal burr

2. Higher precision and stability: with frequent material changes, the motorized focus position adjustment leads to reduced intervention times for the machine operator. Different thicknesses and materials can be cut very flexibly. Thanks to this automated adjustment, even at high accelerations of up to 3 g. It is also the best in class in all other performance features.

3. Completely dust-tight: The LightCutter 2.0 is designed for high laser power. It is completely dust-tight, which guarantees a continuous, clean operation.

4. The basis for clean cut edges is provided by the ultra-stable and drift-free sensor technology for a constant distance between component and optics, which is good for temperature and plasma-resistant distance control

5. Flexible: different fiber plugs (QBH, D, etc.), motorized or manual focus adjustment, customized configurations for all applications

6. Convenient: simple setting of focal position in lateral/vertical direction, additional protective glass in collimation module, rapid changing of protective glass cartridge (no tools required)

7. Slim and sturdy design: it has a very robust design, is lightweight and convinces even after long cutting cycles. No other head generates comparable stable results in this class.

ProCutter 2.0

The Best – Made Even Better

The new ProCutter 2.0 generation impresses with its increased performance and new automation features. Faster, easier, more efficient, more enduring – this is how laser cutting is shaping up in the new generation, due to numerous developments. One of the main reasons for this is the completely redesigned cutting gas flow. In addition, the reliability and power capability has been perfected – up to the maximum laser power of 30 kW. By default, the ability to exchange the nozzles automatically is now provided. The compact design is maintained, together with the extensive sensor technology, which has been specifically expanded to ensure even safer operation.

1. Adjustment of focal position: fully motorized via machine control

2. Focusing lens: X/Y adjustment, no repositioning after changing necessary, additional protective window below focusing lens

3. LED bar: for immediate display of the current system state (pressure, temperature, drive, contamination)

4. Distance measurement: fast, precise, drift-free distance measurement at any operating temperatures, even at high accelerations

5. External interface: output of all sensor data to APP or machine control, readout the values via WLAN, setting of thresholds