Fiber laser cutting head has three major consumables: protective lens, nozzle, ceramic.

Ceramic is located above the nozzle and under the sensor, which is responsible for transmitting and collecting the cutting signal emitted by the nozzle, so as to prevent the nozzle from colliding with the plate during cutting and damaging other parts of the cutting head. So it is important to choose a good quality ceramic.

We provide different size of ceramic for raytools cutting head, such as BM111, BM114, BM115, etc.

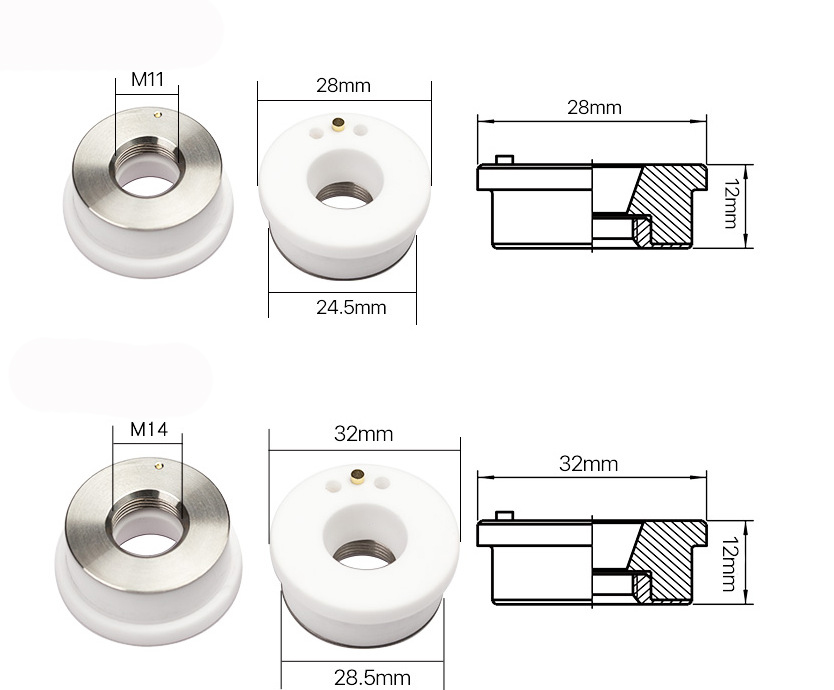

| Newlaz’s code | Diameter | Height | Screw | Application |

| RTL100001 | 28/24.5 | 12 | M11 | BM115 |

| RTC00001 | 32/28.5 | 12 | M14 | BM111, BM114 |

1. Material: high quality ceramic+ special alloy, which ensure consistency of thermal expansion of different parts of ceramic to avoid crack.

2. Stable signal with high sensitivity: use good conductive silver Ink and gold plated copper needle to promise high electric conductivity, high sensitivity, good following character. It can insulate well and reduce some damages caused by senser striking.

3. Good craft: ceramic matches alloy well, ceramic won’t deform. Smooth surface let the air flow more smoothly.