| Item | BM111 | BM114 | BM115 |

| Max. laser power | Average 3300W | Average 6000W | Average 8000W |

| Laser light cable receiver | QBH,QD | QBH,QD | QBH,QD |

| Focal length of collimating lens | 100mm | 100mm | 100mm |

| Focal length of focusing lens | 125mm,150mm,200mm | 150mm,200mm | 150mm,200mm |

| Focusing protective lens | φ27.9mm*4.1mm | φ37mm*7mm | φ3 |

| Collimating protective lens | φ24.9mm*1.5mm | φ38mm*1.5mm | φ38mm*1.5mm |

| Auto focus range | +10~-12mm | +10~-14mm | +15 ~ -20(FL150) +20 ~ -25(FL200) |

| Auto focus Acceleration | ≤10m/s² | ≤10m/s² | ≤10m/s² |

| Auto focus speed | ≤10m/min | ≤10m/min | ≤15m/min |

| Auto focus Accuracy | ≤50μm | ≤50μm | ≤50μm |

| Nozzle aperture | 0.8mm-5.0mm | 0.8mm-5.0mm | 0.8mm-5.0mm |

| Clear aperture | 28mm | 35mm | 36.1mm |

| Shielding gas pressure | ≤30bar | ≤30bar | ≤30bar |

| Weight | ~5.7kg | ~5.6kg | >6.5kg |

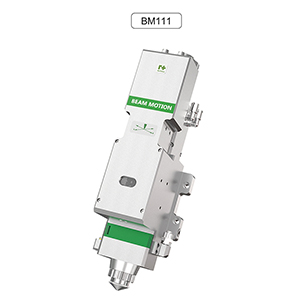

BM111 3.3kW

High-performance Automatic Focusing Cutting Head

1. Multiple cover glass protection: total 3pcs protective lens to protect focusing and collimating lens

2. Excellent dustproof: IP65 class dustproof, patented protection cover glass catridge, ALL-body have anti-dust design

3. Auto-focusing: reducing human intervention, Max focusing speed 10/min, repeat accuracy 50μm

4. High-speed cutting: based on 3kW, cutting 12mm SUS304 at 0.6m/min, cutting 12mm Q235 at 1.2m/min

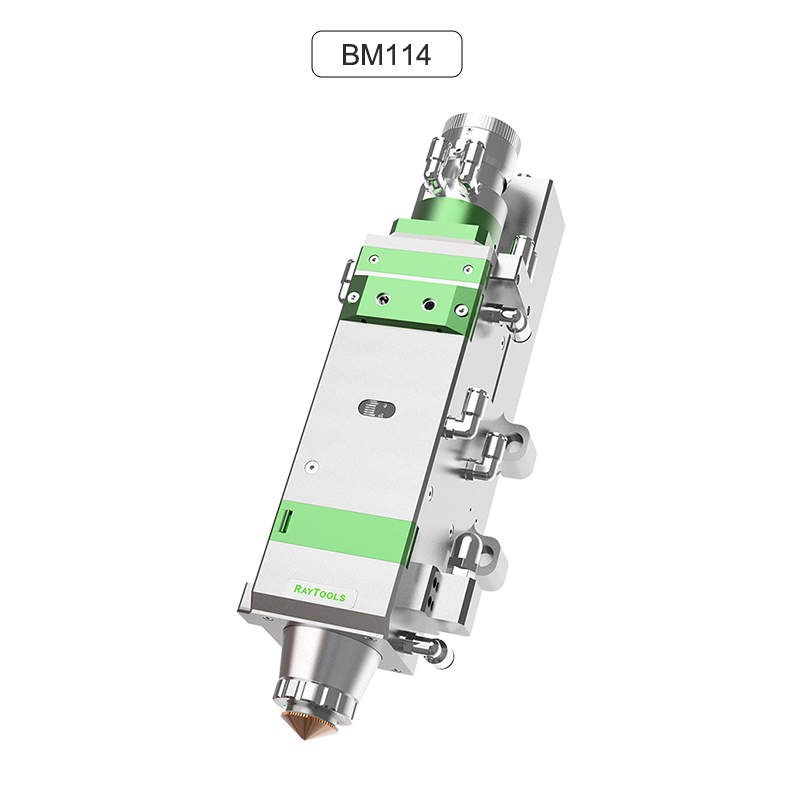

BM114 4/6kW

Economical Medium And High Power Automatic Focusing Cutting Head

1. High efficiency cooling: collimation and focusing lens are both cooled by water, air flow cooling is increased for nozzle, which can effectively protect the nozzle and ceramic, increase lifetime.

2. Auto-focusing: reducing human intervention, Max focusing speed 10/min, repeat accuracy 50μm

3. High-speed piercing and cutting: based on 3kW, pierces up to 25mm mild steel in 3 sec

4. Large clear aperture: 35mm clear aperture, effectively reducing stray light interference, guarantee cutting quality and lifetime.

5. Portable and durable: 5.6kg, compact structure, reduce the mechanical requirements.

6. High power rating: rate to 6.3kW, with D37 lens group, it’s easier to cut thick plate

BM115 6/8/12kW

High Power Automatic Focusing Cutting Head

1. High efficiency cooling: collimation and focusing lens are both cooled by water, air flow cooling is increased for nozzle, which can effectively protect the nozzle and ceramic, increase lifetime.

2. Fast zoom: using collimation to focus, compared focusing to focus, which moves faster with larger focusing range.

3. Large clear aperture: 35mm/36.1mm clear aperture, effectively reducing stray light interference, guarantee cutting quality and lifetime.

4. Excellent design: the integrated body design ensures to seal completely. Improvement of QBH QD Q+ fiber interface improves the compatibility of the laser source. Don’t get stuck due to water leakage, rust, etc any longer.

5. High power rating: rate to 12kW, with D37/D38 lens group, it’s easier to cut thicker plate