Laser has been widely known in the field of metal cutting, but many people still do not know how to judge the cutting quality, what they only know is to check smoothness of surface. In fact, the cutting quality is usually judged from the perspectives of section roughness, bottom burr, verticality, kerf width, etc. Let’s take a look at the evaluation criteria of the cutting quality of fiber laser cutting machine.

1. Section Roughness

Laser cutting is affected by auxiliary gas flow and running speed, vertical or inclined lines will be formed on the cross section, and the depth of the lines determines the roughness of the section. The darker the texture, the rougher the section, and the lighter the texture, the smoother the section. Roughness affects not only the appearance of edges, but also friction. The lower the roughness of the plates, the higher the accuracy, so it is necessary to reduce the roughness as much as possible. The cutting accuracy can be adjusted by some factors such as laser power, cutting speed, focal length, auxiliary gas type and air pressure.

2. Bottom Burr

The principle of laser cutting is that a high-energy laser beam vaporizes the metal surface, and the slag on the surface of the plates is blown away by an auxiliary gas. However, in the actual cutting process, due to the mismatch of different factors such as laser power, operating speed, auxiliary gas type and air pressure, some slag will not be blown away after cooling, and burrs will form on the surface and hang on the bottom of the plates. So secondary processing is required, which is very time-consuming. The burr and slag at the bottom of the plates are one of the most important criteria for judging the cutting quality.

3. Verticality

For thin plates, verticality can be negligible. But when the thickness exceeds 10mm, the verticality of the cutting edge is very important. The laser beam is emitted in a cone shape. When it’s far away from the focal point, the laser beam becomes divergent. Depending on the position of the focal point, the cutting surface will widen towards the bottom or top. The more vertical the edge, the higher the quality of the cut.

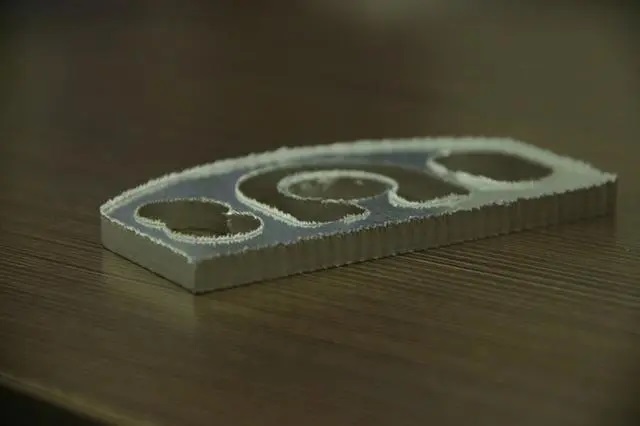

4. Kerf Width

The width of the kerf is the embodiment of the processing accuracy, which usually does not affect the cutting quality, but only affects the material cost. When a particularly precise contour and pattern need to be formed inside the plates, the kerf width will become an important indicator. This is because the kerf width determines the minimum inner diameter of the contour. The smaller the kerf width, the more precise the contour. This is one of the important advantages of laser cutting instead of plasma cutting. However, with the increase of plates thickness, the width of the kerf will inevitably increase. To ensure stable high-precision cutting, it is necessary to ensure that the plates is stable in the processing area of the laser cutting machine no matter how large the cutting width is.

5. Texture

When cutting thick plates at high speed, the molten metal does not appear in the kerf below the vertical laser beam, but instead sprays out at the back of the laser beam. As lines follow the moving laser beam, curved lines are formed at the cutting edge. To correct this problem, reducing the feed rate at the end of the cutting process can greatly eliminate the formation of lines.

6. Material Deposition

Before melting, laser cutting machine will touch a layer of oil-containing special liquid on the surface of the plates. During the cutting process, even if blowing the cut with air due to vaporization, the upward or downward discharge will also form deposits on the surface.

7. Deformation

In laser cutting, the area around the cut is heated. At the same time, the structure of the metal changes. For example, some metals will harden.

Depression and corrosion have a detrimental effect on the surface of the cut edge, affecting the appearance. They appear in cutting errors that should generally be avoided. If the cutting causes a part to heat up sharply, it will deform. It is especially important in precise processing, as contours and webs are usually very thin.