Choosing nozzle is one of the most important parts during cutting. So how to choose nozzles for different power of cutting machine?

During the laser cutting process, the nozzle collects the capacitance signal and transmits it to the signal processor through the ceramic, thereby maintaining the distance tracking of the laser cutting head to the workpiece during the cutting process, and guiding the gas to pass through the workpiece to be cut smoothly, and speeding up the cutting speed, taking away slag to protect the mirror inside laser cutting head.

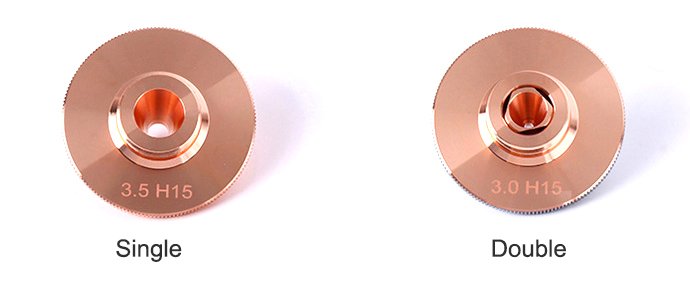

1. Single Nozzle or Double Nozzle

There are two types of nozzles: single layers and double layers. Single layer nozzles are suitable for melting and cutting, and nitrogen is commonly used as auxiliary gas, which is usually used for cutting stainless steel, aluminum alloy, etc; Double layer nozzles are used for oxidation cutting, and oxygen is used as auxiliary gas for carbon steel cutting.

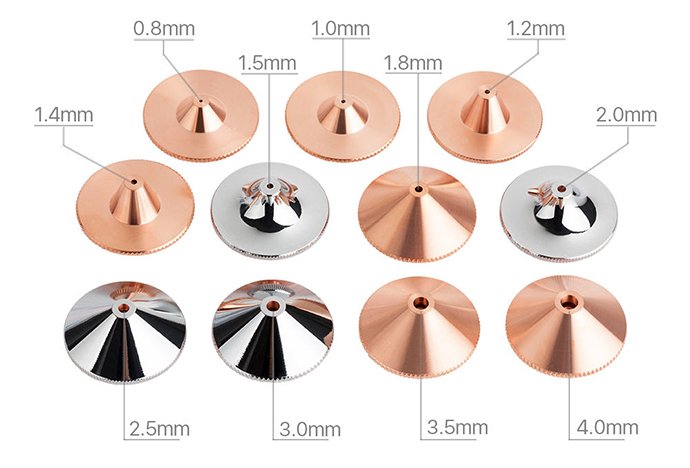

2. About Nozzles Diameter

Different diameter is used for plates cutting of different thickness. Diameter of nozzles determines the shape of the gas flow entering the incision, the diffusion area of the gas, and the flow rate of the gas, which affects the removal of the melt and the stable cutting, which is very important for the quality of the cutting.

The greater the air flow into the notch, the faster the speed, and the proper position of the workpiece in the air flow, the stronger the ability of jet to remove melt.

You can choose different nozzles diameter based on power of fiber laser source, thickness of plates. In theory, the thicker the plate is, the larger the nozzle diameter should be.

Nozzles diameter: 0.8, 1.0, 1.2, 1.5, 1.8, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, etc, and the most used ones are: 1.0, 1.2, 1.5, 2.0, 2.5, 3.0, and the three most frequently used are 1.0, 1.5, and 2.0.

Usually when laser cutting machines cut thin plates under 3mm, it’s better to choose 1mm(1.5mm diameter is a little large, the corners are more prone to melting stains), it’s better to choose 1.5mm when cutting plates thicker than 3mm(the cutting power is high, the heat dissipation time is long relatively, and the cutting time also increases. The gas diffusion area of 1.5mm nozzles is large, the flow of gas is slow, cutting is relatively stable. 2mm or more is suitable for cutting 10mm plates).