The size of the laser power directly affects the thickness of the steel plate that can be cut. The higher the energy, the thicker the cutting material.

In addition, it affects the dimension precision of the workpiece, the width of the cutting, the roughness of the cutting surface and the width of the heat affected zone.

Laser power density P0 (W/cm²) and energy density E0(J/cm²) illuminated on the workpiece in the laser cutting process have an important influence on the laser cutting process.

With the increase of laser power density, the roughness decreases. When the power density P0 reaches a certain value (about 3*106W/cm²), the roughness Rz value no longer decreases.

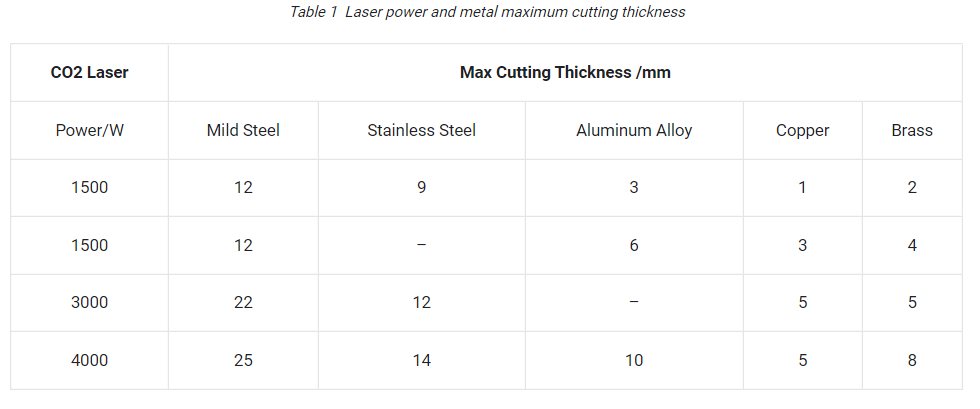

The larger the laser power, the thicker the material that can be cut. But for the same power laser, the thickness that can be cut will be different for different materials.

Table 1 shows the maximum thickness for CO2 laser cutting of various power of some metal materials.

For laser generator with continuous-wave output, the laser power size and mode will have an important influence on the cutting quality.

In practice, the maximum power is often set to obtain the fastest cutting speed, to improve the production efficiency, or to cut the thicker material.

In theory, the larger the output the better.

But considering the cost of the laser generator, the output power of the laser generator should only be set close to the maximum output power of the cutting machine.

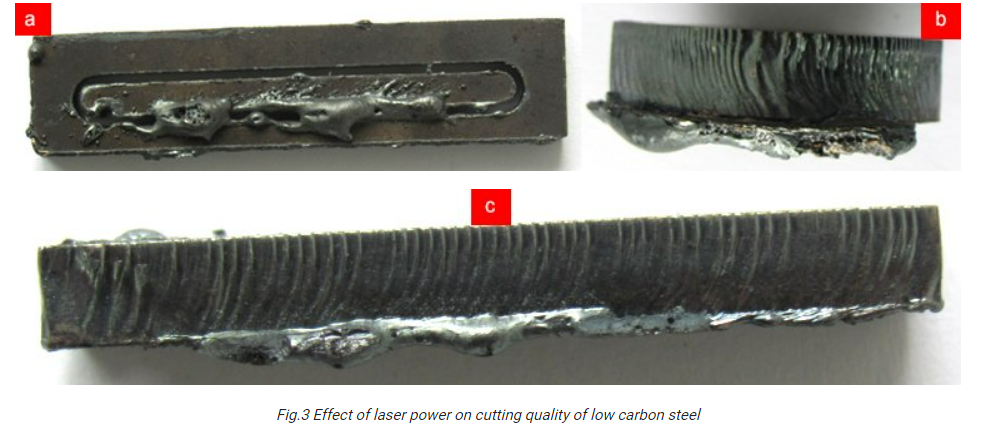

The following figure shows the problem of cutting low carbon steel plates when the laser power is insufficient (a. not cutting through; b. the lower part produces a lot of slags; c. rough section)

cr: machinemfg