Air, the “gas of life“, we breathe every day, is a mixture of 78% nitrogen, 21% oxygen, 0.94% rare gases (helium, neon, argon, krypton, xenon), 0.03% carbon dioxide, 0.03% other substances (such as water vapor, impurities, etc.).

In the process of laser cutting, what are the advantages of air cutting?

Today, let’s learn about it.

Principle of air cutting

In fact the cutting principle of air is similar to that of nitrogen.

It depends on the energy of laser to melt the metal, and uses high pressure to blow away the melt.

During this period, some metal substances will oxidize or burn, forming metal oxides on the cutting surface.

For example, grey solid AI2O3 (alumina), black solid Fe3O4(black iron oxide) and CuO (copper oxide) are generated.

The air itself exists in the atmosphere.

It can be used after being compressed to the air storage tank by the air compressor, and then filtered, cooled and dried to remove the water and oil in the air.

Since the air contains about 21 % oxygen, it can make up for the lack of oxygen and nitrogen to a certain extent.

Theoretically, air can cut all metal materials that can be melted by laser energy.

Air cutting efficiency and effect experiment

The effect test of cutting stainless steel, carbon steel and aluminum alloy plates with 6kW laser cutting machine using air and nitrogen / oxygen respectively.

Experiment 1: comparison of nitrogen and air cutting stainless steel

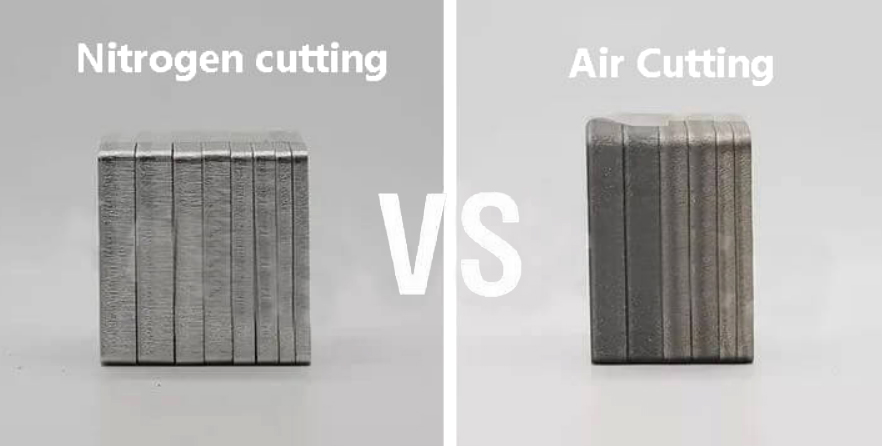

1. Comparison of nitrogen and air cutting section effect

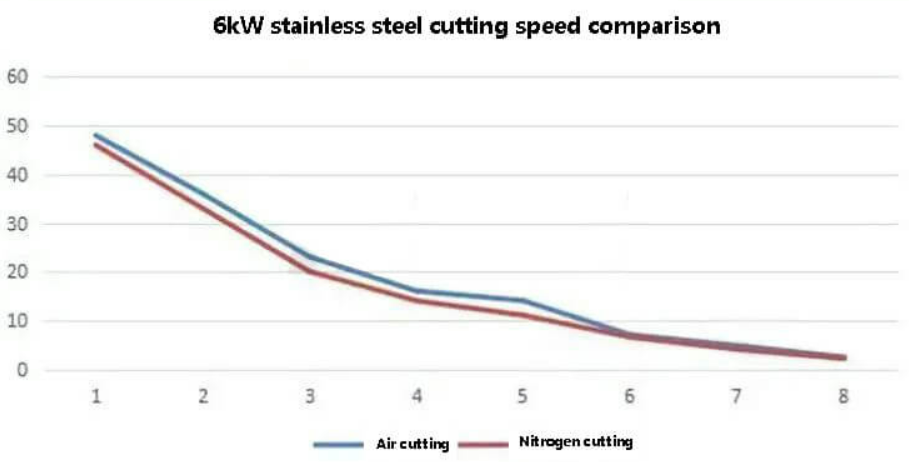

2. Comparison of nitrogen and air cutting speed

Effect analysis:

The above figure shows the cutting effect of 10mm to 4mm stainless steel in turn.

Compared with nitrogen cutting, the section cut by air is darken but there is no slag.

After polishing, the section can also achieve a brighter effect.

In terms of speed, air cutting stainless steel is slightly faster than nitrogen, but the advantage is not obvious.

Experiment 2: comparison of oxygen and air cutting carbon steel

1. Comparison of oxygen and air cutting section effects

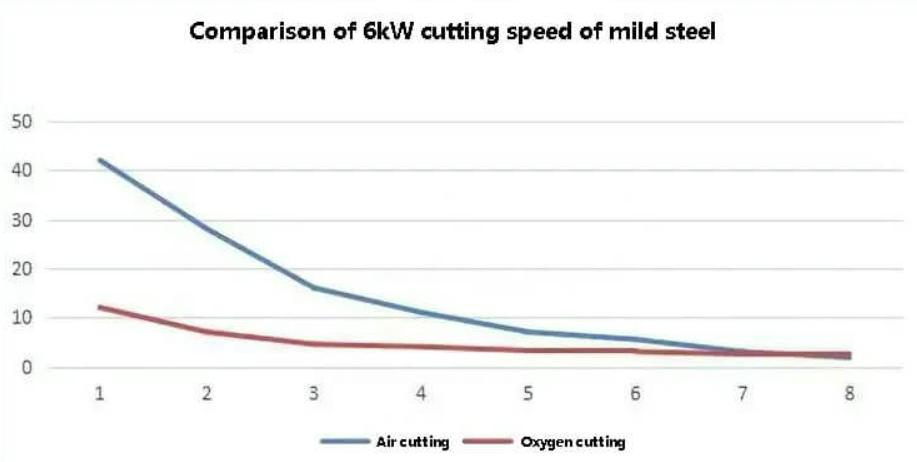

2. Comparison of air and oxygen cutting speed

Effect analysis:

The above fig. shows the cutting effect of 10mm to 3mm carbon steel in turn.

Compared with oxygen cutting, 8mm carbon steel has slight slag hanging, and 10mm slag hanging is more serious.

Therefore, air cutting is not recommended for cutting carbon steel plates above 10mm.

Experiment 3: comparison of nitrogen and air cutting aluminum alloy

1. Comparison of nitrogen and air cutting section effect

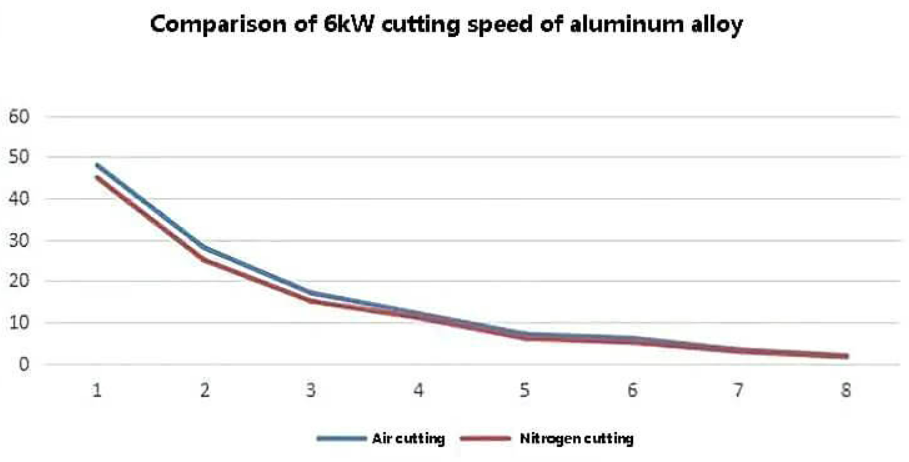

2. Comparison of nitrogen and air cutting speed

Effect analysis:

The above figure shows the cutting effect of 10mm to 3mm aluminum plate in turn.

Compared with nitrogen cutting, air cutting has fine section and less slag hanging.

In terms of speed, air cutting aluminum plate is slightly faster than nitrogen, but the advantage is not obvious.

Summary

Through experiments, we made a comparison of the effect and efficiency of air and nitrogen / oxygen cutting when cutting plates of different materials and thicknesses.

Considering comprehensively, under the condition of relatively loose requirements, we can choose air cutting with greater cost advantages.

Relatively speaking, the combination of using air as cutting auxiliary gas is also a way to greatly reduce production costs.

But it should be noted that:

When using compressed air for cutting, it must be ensured that the compressed air is dewatered by the cold dryer, with a pressure dew point of 3-8 ℃, and also subject to multi-stage degreasing treatment.

Not only the liquid oil content reaches 0.003ppm, but also the vapor oil content reaches 0.003ppm, so it is necessary to add a filter that can specifically remove the gaseous oil.

In order to ensure the drying of low oil compressed air, the air compressor, cold dryer and filter must be maintained regularly.

If the air entering the cutting head contains water and oil, it will pollute the gas pipeline in a short time, causing fog on the protective lens, thus affecting the cutting quality.

In addition, if the protective mirror is not replaced in time, the internal temperature of the cutting head may rise under the irradiation of high-power beam, which may cause damage to the internal mirror group.

In the production process, only by considering the cutting efficiency, cutting cost and cutting effect, can we find the most cost-effective cutting scheme that is most suitable for the current cutting needs, and bring us higher quality production!