Now more and more manufactures choose fiber laser machine to cut metal sheet. Because it can create more economic benefits. There are also many people whose CO2 laser cutting machine in good condition, but no enough money to purchase a new fiber laser cutting machine. What they can do?

Difficult Position

Due to CO2 laser dominating the metal sheet cutting market since 1970, many manufactures still use CO2 laser machine to cutting at present. Machine is still in good condition, and it’s a large expense to purchase a new fiber laser cutting machine, they are caught between large maintenance cost and electricity cost, etc without any methods.

New Turn

Newlaz also find this problem and work out a new and better solution. We can retrofit you old CO2 laser cutting machine to fiber lase source within 3 days without change any system and motors. More than one hundred customers all around world have solved this problem under our retrofit solution. And our experienced fitters can give technical support in 24h.

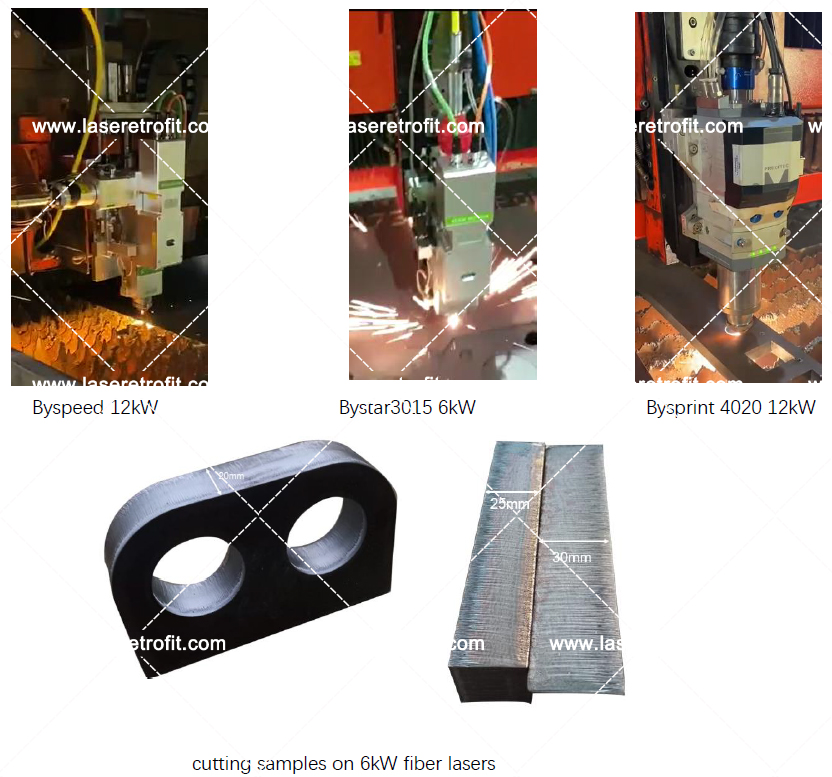

Bystronic Retrofit Solution

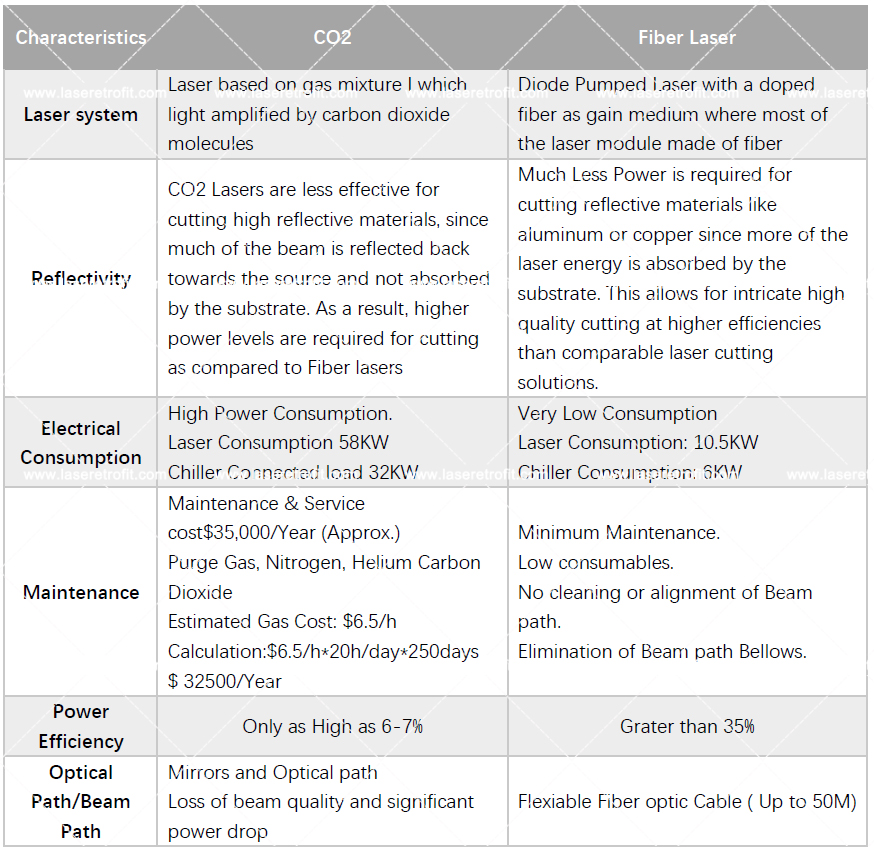

Maybe you just hear fiber laser is better than CO2 fiber machine from others, but don’t know how it exactly advantages. Below is the comparison about these two machines based on 3kw for your reference.

As we all know, bystronic CO2 cutting machine is a precision machine, you can image how difficult to upgrade it with fiber laser source without change any system. Newlaz team achieve it with our own core technology.

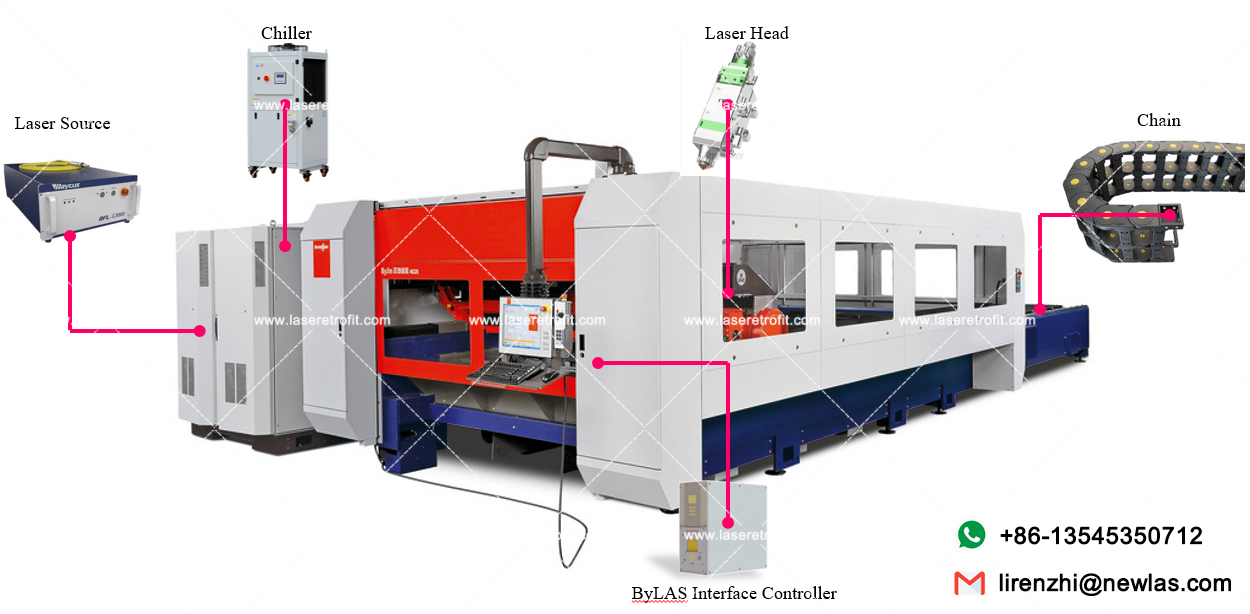

You just need to change laser source, chiller, cutting head, chain, etc and increase our controller which will take about 3 days, it’s convenient and efficient.

What you can get after retrofitting?

1. Original CNC system: keep existing operating methods you are familiar

2. More Efficient:

a. 100% reuse of equipment, your old CO2 machine still can work for long time.

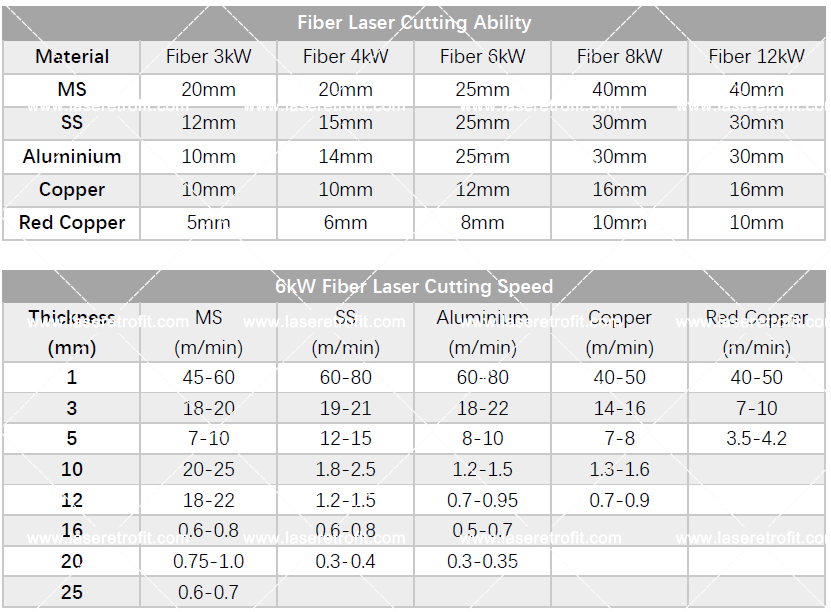

b. 30% increase in efficiency: good cutting ability and faster cutting speed

c. 50% reduction of operating costs, much less maintenance cost and time. Fiber laser don’t need gas to generate laser and can use air to cut, gas cost will be reduced greatly.

3. Warranty:

a. 2 years warranty for fiber laser source

b. 24h technical support

Retrofit Case